Concrete is a popular building material because it’s strong, lasts a long time, and can be shaped in many ways. It is used in building bridges, roads, buildings, and many other structures. But to make sure concrete is smooth, strong, and long-lasting, we must be very careful when we pour it and let it dry. If we are not careful, concrete can have problems that might make it weaker. One problem that can happen during construction is a “cold joint.”

When concrete is poured in sections or layers without proper connection between the pours, In the concrete, joints become cold. This break or gap between layers can cause a visible line or separation within the concrete, which might weaken the structure. Understanding the causes of cold joints, how they affect concrete, and how to prevent or fix them is important for building strong and durable structures. In this article, we will learn about cold joints, what causes them, and how we can stop or fix them to keep concrete structures strong.

What is a Cold Joint?

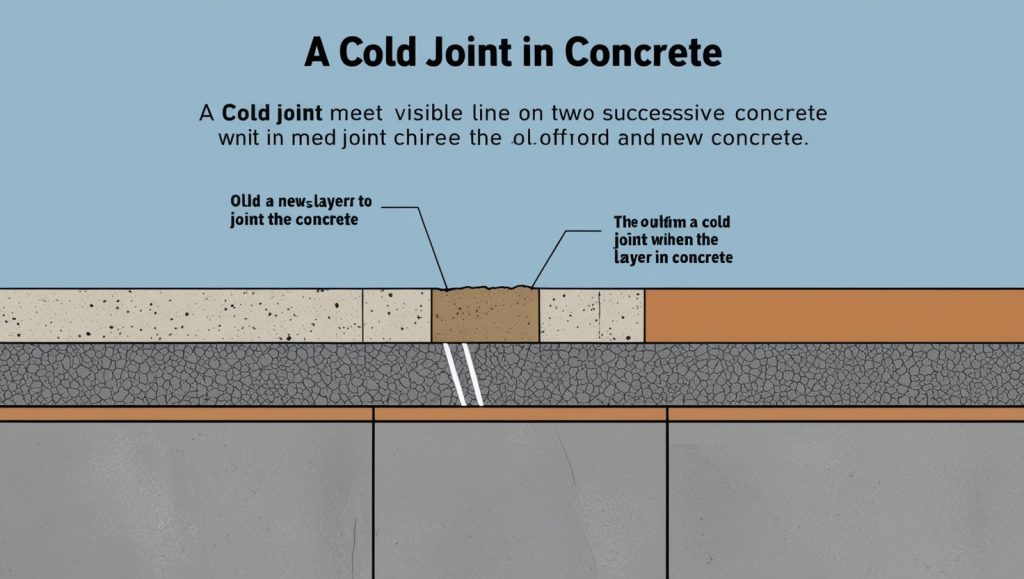

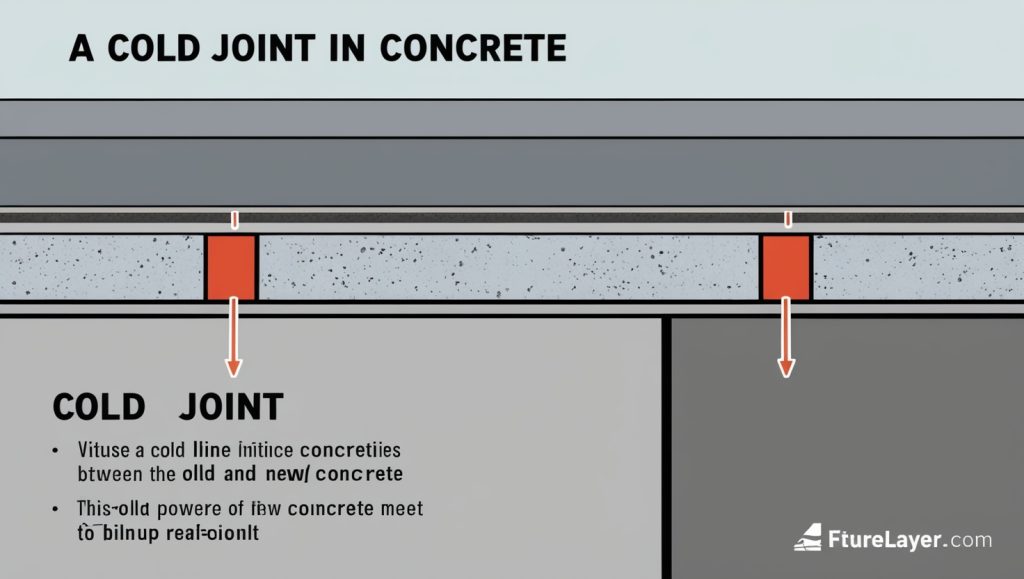

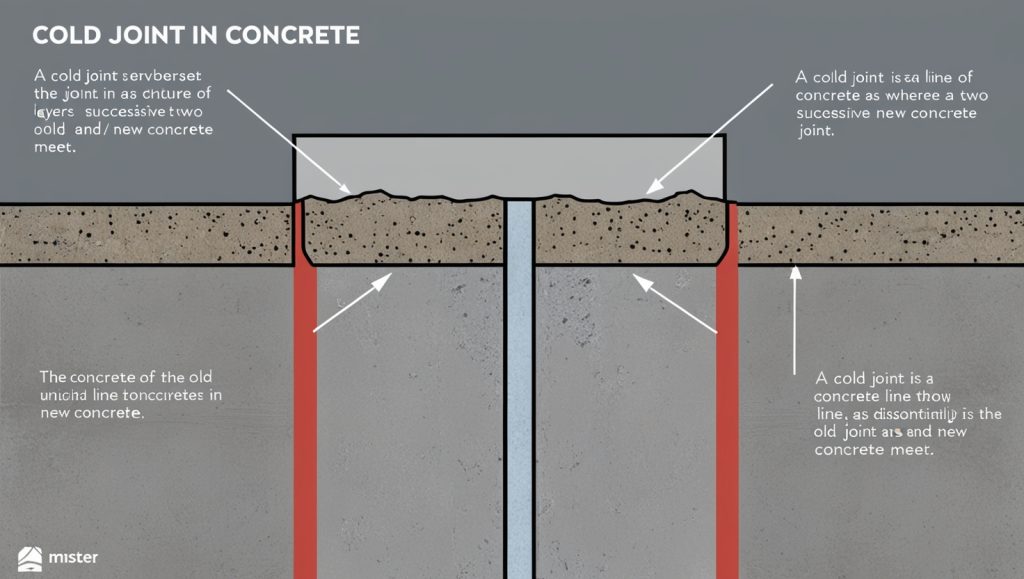

When two separate batches of concrete are poured at different times, they fail to mix well, resulting in a cold joint. Imagine you’re pouring a cake batter into a mold. If you wait too long between adding the layers, the layers won’t blend together properly, and you’ll see lines between them. That’s what happens with concrete in cold joints. When the next layer of concrete is not added before the first layer starts to dry, a cold joint forms.

This line or gap can make the concrete weaker. Concrete should be one solid piece, without any separations, so it can hold up to pressure and last a long time. Cold joints make weak spots in the concrete, which might make it crack or break over time.

Cold joints happen when there is too much time between pouring the concrete. Fresh concrete should stick to the layer that was already poured to make one strong and continuous structure. If a cold joint forms, the bond between the layers might not be strong enough, which can cause future problems like cracking, water leaks, or even a failure of the structure in extreme cases.

Why Concrete is Important in Construction

Before we go further, let’s understand why concrete is so important in construction. Concrete is used almost everywhere because it is very strong and can last for many years if made properly. It is used in buildings, roads, bridges, dams, and even sidewalks. Concrete is made from mixing cement, water, sand, and rocks. When these materials are mixed together, they harden into a strong solid.

Concrete is important because:

- It can carry heavy weights: Concrete is used to build big buildings and bridges because it can support a lot of weight.

- It lasts a long time: Concrete doesn’t break down easily over time. If it’s made and cared for correctly, it can last for decades.

- It is versatile: Concrete can be shaped into different forms when wet, making it useful for all kinds of projects.

But even though concrete is strong, it needs to be handled with care during construction to avoid problems like cold joints, which can make the concrete weaker.

Causes of Cold Joint in concrete

Several factors can lead to cold joint in concrete. Understanding these causes helps builders avoid cold joints and make stronger concrete structures. Here are the main causes of cold joints:

- Delayed Pouring: Cold joints often happen when there is too much time between pouring batches of concrete. Concrete starts to set and dry after it is poured. If you wait too long before pouring the next batch, the first layer will have started to dry, and it won’t bond properly with the new layer. This creates a cold joint. Delays can happen due to bad planning or problems with delivering the concrete to the construction site.

- Bad Formwork: The formwork is the structure that holds the wet concrete in place while it dries and hardens. If the formwork is broken or set up incorrectly, it can cause the concrete to settle unevenly. This unevenness might create gaps between the concrete layers, leading to cold joints. The formwork must be straight and strong so that the concrete layers bond together well.

- Different Concrete Mixes: Sometimes, if the mix of concrete is different between pours, the layers won’t bond well. For example, one batch might be too thick, while the next one might be too thin. This difference in the mix can cause the concrete layers not to stick together properly, leading to cold joints.

- Improper Curing: Concrete needs time and moisture to cure, which means harden and gain strength. If the curing process is not done right, the layers won’t bond well. Concrete that dries too quickly or doesn’t get enough water can become weak and form cold joints.

Effects of Cold Joints in concrete

Cold joints can have several negative effects on concrete structures. Knowing these effects helps builders fix or prevent cold joints so that the concrete stays strong. Here are some of the main effects of cold joints:

- Weaker Concrete: Cold joints in concrete create weak points in the concrete. These weak points can reduce the concrete’s strength and ability to carry heavy loads. If the layers don’t bond well, the concrete might crack or break more easily, especially when under pressure.

- Water Leaks: Cold joints can create small gaps or cracks in the concrete. Water can get into these gaps and cause problems, especially in structures like bridges, buildings, and dams. When water seeps in, it can rust the steel inside the concrete, which weakens the entire structure.

- Appearance: Cold joints can create visible lines in the concrete, which can look bad, especially in places where the concrete is exposed. For example, in decorative concrete walls or floors, cold joints can ruin the smooth and polished look that builders want.

Preventing Cold Joints

To avoid cold joints and make strong concrete structures, builders can follow these important steps:

- Plan Ahead: Planning the work schedule is very important. Make sure there is enough time to pour the next batch of concrete before the first one starts to dry. Good planning helps avoid delays and keeps the work moving smoothly. If construction is interrupted for too long, cold joints are more likely to form.

- Keep the Concrete Soft: Concrete must stay soft and workable for as long as possible before it hardens. This helps the different layers bond together better. Builders must check that the concrete doesn’t start setting too early before the next layer is poured.

- Use Bonding Agents: In cases where a delay is unavoidable, builders can use bonding agents. These special materials help new concrete stick to the old layer more strongly, reducing the chance of cold joints.

- Cure the Concrete Properly: After concrete is poured, it needs to be cured properly. This means keeping it moist so it doesn’t dry out too quickly. Builders can cover the concrete with wet cloths or use water sprays to keep it damp, which helps it cure properly and prevents cold joints.

Fixing Cold Joints

If a cold joint forms in a concrete structure, it’s important to fix it as soon as possible. Here are some ways to repair cold joints:

- Clean and Repair the Joint: To fix a cold joint, builders can clean the joint and apply a bonding agent to make sure the new concrete sticks well to the old concrete. After this, they can fill the joint with new concrete or a special repair material to make the surface smooth and strong again.

- Seal the Joint: If water is leaking through a cold joint, builders can seal the joint with special sealants. These sealants stop water from getting in and protect the concrete from damage. The right sealant should be chosen based on the location and type of structure.

- Add Reinforcement: In some cases, builders may need to add extra steel bars or other reinforcing materials to make sure the structure stays strong, even if there is a cold joint. This helps it stay solid and resist cracking or breaking.

Conclusion

Cold joints in concrete can create problems that affect the strength, durability, and appearance of structures. By understanding the causes of cold joints, such as delayed pouring, bad formwork, and improper curing, builders can take steps to avoid them. Preventing cold joints is important to ensure that concrete structures are strong, safe, and long-lasting.

If cold joints do form, repairing them quickly can prevent more serious problems in the future. Using bonding agents, sealing joints, and reinforcing structures are all ways to fix cold joints and maintain the strength of the concrete.

In construction, paying attention to detail and following best practices helps ensure that concrete projects are successful and durable. By preventing cold joints, builders can create strong, reliable structures that stand the test of time.

if you want to know Concrete Insulation R-Value, click here

FAQs

A cold joint is a separation or line that appears when two batches of concrete are poured at different times and don’t mix well. This usually happens when the first layer starts to harden before the next one is poured, leading to a weak point in the structure.

Cold joints can create weak spots in the concrete because the two layers don’t bond together as one solid mass. This makes the concrete less able to support heavy loads, increasing the chances of cracks or structural failure over time.

Cold joints are mainly caused by delays between pouring batches of concrete. Other causes include poor formwork, differences in concrete mix, or improper curing. These factors prevent the layers from bonding properly, creating weak points in the structure.

Yes, cold joints can create tiny gaps where water can seep through. Over time, this water can cause damage by rusting the steel reinforcements inside the concrete or by weakening the concrete itself, reducing its durability.

Preventing cold joints requires good planning and continuous pouring without long delays. Ensuring the concrete remains workable, using bonding agents if there’s a delay, and properly curing the concrete all help prevent cold joints from forming.

To fix a cold joint, you must clean the joint surface to remove any dirt or loose material. Then, apply a bonding agent to help the new concrete stick to the old layer. Afterward, fill the joint with fresh concrete or a special repair material to ensure the surface is smooth and solid again.

Yes, sealing cold joints with waterproof sealants can help prevent water from getting inside. This is particularly important for structures like bridges, dams, or basements, where water damage could weaken the entire structure.

Cold joints often create visible lines or marks on the surface of the concrete, which can look unattractive, especially in areas where the concrete is exposed. These lines may spoil the smooth, finished look of concrete surfaces, especially in decorative or visible areas.

Cold joints may not cause immediate damage, but over time, they can weaken the structure, especially if water leaks through. The longer cold joints are left untreated, the more likely they are to lead to cracks, breaks, or other serious issues that could compromise the structure’s integrity.

To repair a cold joint, you’ll need tools to clean the joint (such as brushes or scrapers), bonding agents to ensure good adhesion, sealants to prevent water leakage, and fresh concrete or patching materials to fill the gap and reinforce the structure.