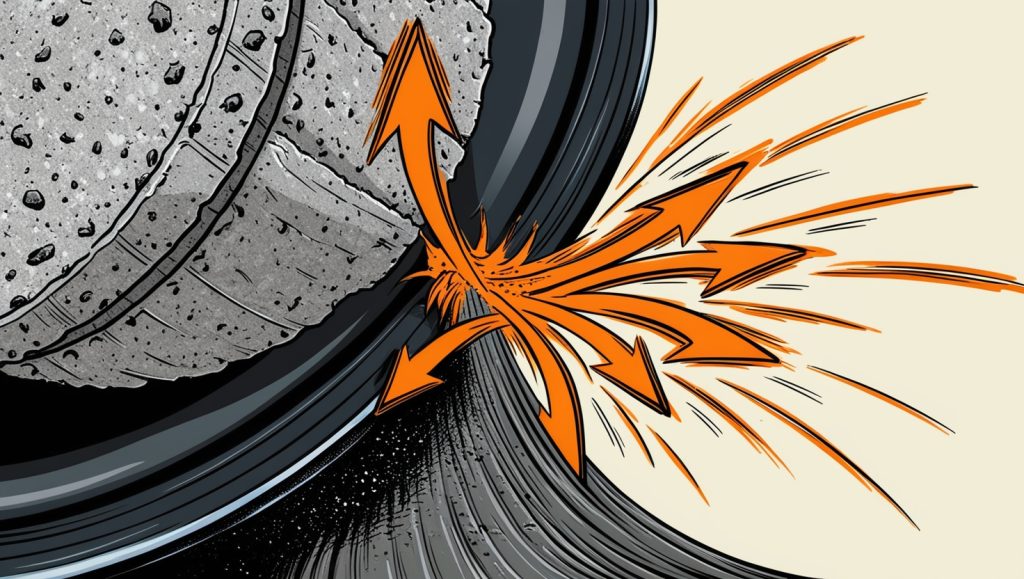

Concrete is a fundamental material in construction due to its strength and durability, but how it interacts with other materials plays a vital role in ensuring the safety and stability of structures. One important aspect of this interaction is the concrete friction coefficient. This coefficient measures the resistance a concrete surface provides when another material slides or slips against it. In simpler terms, it tells us how much friction the concrete generates.

This friction coefficient is essential in many construction applications, such as roadways, bridges, and building floors, where materials like rubber or steel come into contact with concrete. A high friction coefficient ensures better traction, preventing slips and accidents, while a low friction coefficient could lead to instability.

Understanding and measuring the friction coefficient allows engineers to choose the right materials and treatments for specific projects. This ensures that structures are not only strong but also safe for vehicles, pedestrians, and equipment, especially in conditions like rain or icy weather, where slip resistance becomes even more critical.

What Is the Friction Coefficient?

The friction coefficient refers to the measure of resistance between a concrete surface and another material when they move against each other. In simpler terms, it indicates how much friction a concrete surface generates.

This coefficient is crucial in designing structures like roads, bridges, and buildings where different materials interact with concrete. It ensures that vehicles, people, and even other materials don’t slip or slide too easily, enhancing the safety and stability of the structure.

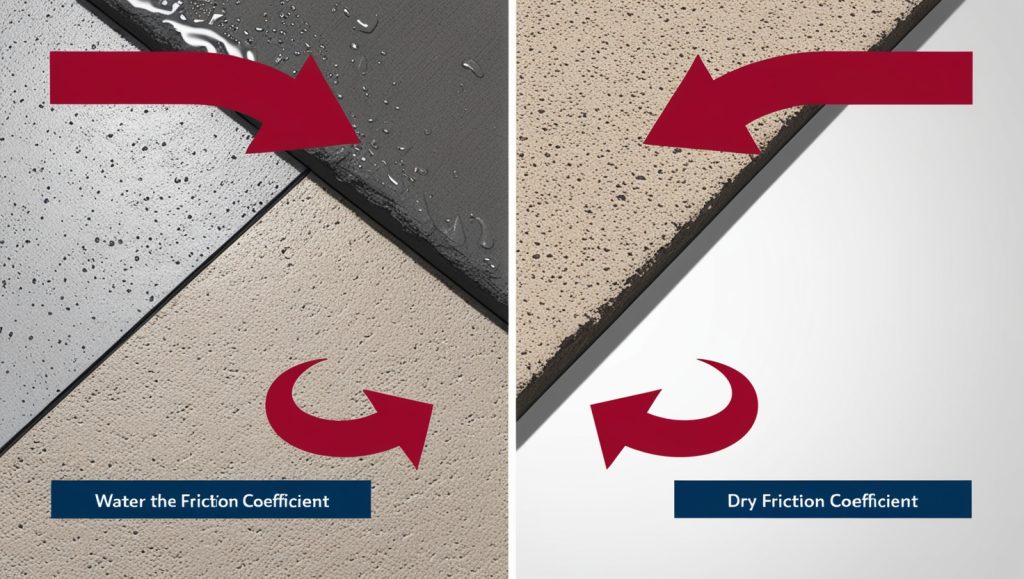

There are two main types of friction that we must consider: static friction and kinetic friction. Static friction occurs when an object is not moving, while kinetic friction happens when there’s motion between two surfaces. The friction coefficient varies depending on the surface texture, moisture level, and the material in contact with the concrete.

Why Is the Friction Coefficient Important?

The friction coefficient is important because it directly impacts safety, durability, and the functionality of various structures. For example, a road with a low friction coefficient can become slippery, increasing the risk of accidents. On the other hand, a high friction coefficient can provide better traction for vehicles and pedestrians, reducing the risk of slipping.

In construction, the friction coefficient determines how different materials, such as steel or rubber, will interact with concrete. A low friction coefficient between concrete and steel could weaken connections, while a higher coefficient ensures more reliable bonding. Therefore, selecting the appropriate materials and understanding their interaction with concrete is critical in preventing accidents and structural failures.

Factors Affecting the Concrete Friction Coefficient

Several factors affect the friction coefficient, and understanding them is essential for accurate measurements and calculations. Some of these factors include:

Surface Texture

Rougher concrete surfaces typically have a higher friction coefficient because there is more resistance. Smooth surfaces, on the other hand, offer less friction.

Moisture Levels

Wet or moist concrete surfaces tend to have a lower friction coefficient compared to dry surfaces. This is why wet roads are often more slippery than dry ones.

Temperature

Extreme temperatures can also affect the friction coefficient of concrete. For example, icy conditions can reduce the coefficient significantly, increasing the risk of slipping and accidents.

Material Interaction

Different materials interacting with concrete will have varying friction coefficients. Rubber, for example, tends to have a high friction coefficient with concrete, making it suitable for tires or footwear.

How to Measure the Concrete Friction Coefficient

We can measure the friction coefficient in different ways, depending on what the project needs. The most common method is using a tribometer, a device that measures the friction between two surfaces. In this test, we press the concrete surface against another material and measure the resistance under controlled conditions.

We use the results to figure out the friction coefficient, and we can adjust it by changing the surface or adding coatings. These measurements are essential in industries like road construction, where high friction is necessary to ensure vehicle safety, or in areas where slip resistance is a priority.

Applications of Concrete Friction Coefficient in Construction

The friction coefficient plays a vital role in various construction sectors. Some of the key applications include:

Road Construction

In road construction, engineers rely on a high friction coefficient to ensure that vehicles have adequate traction. This helps prevent skidding, especially during rainy or icy conditions.

Bridges

Bridges must maintain strong contact between the concrete surface and the tires of vehicles. A higher friction coefficient ensures that vehicles don’t lose control while crossing.

Flooring in Buildings

The friction coefficient is equally important in buildings, especially in areas like staircases, walkways, or parking lots. A slip-resistant concrete surface ensures the safety of pedestrians, reducing the chances of accidents.

Industrial Use

In factories, we must control the friction between concrete floors and heavy machines to stop slipping, which could cause accidents or damage.

Enhancing the Concrete Friction Coefficient

There are various methods to improve the concrete friction coefficient based on the needs of a project. One popular approach is surface treatment, which involves altering the concrete’s texture to make it rougher.

We can do this by grinding, blasting, or adding special coatings to make the surface rougher. These methods help create a surface that offers better grip, reducing the likelihood of slipping or sliding.

Another effective method is adding aggregates, such as sand or gravel, directly into the concrete mix. These materials create a naturally rough surface, increasing the friction coefficient and improving traction.

This is particularly useful in places like roadways, where vehicles need reliable grip, or in industrial settings, where slip resistance is essential for safety. By applying these techniques, engineers can ensure that concrete surfaces are not only strong but also provide the necessary friction for safe use.

Conclusion

It’s important to understand the concrete friction coefficient for anyone working in construction or engineering. It affects not only the durability and functionality of structures but also their safety. By thinking about surface texture, moisture, and how materials interact, engineers can make sure their projects are safe.

In construction, knowing how to measure and enhance the friction coefficient of concrete is key to building roads, bridges, and buildings that are safe, durable, and reliable. By managing this vital factor, construction professionals can minimize the risk of accidents and structural failures, creating a safer environment for everyone.

You can get more enhanced information about Tying Reinforcing Steel, Click here

FAQs

The concrete friction coefficient measures the resistance between a concrete surface and another material when they move against each other. It indicates how much friction the concrete generates and is essential for ensuring safety in structures like roads and buildings.

The friction coefficient is crucial for safety and stability. A higher coefficient provides better traction, reducing the risk of slipping or accidents, while a lower coefficient may lead to instability in structures or increased risk of sliding.

Several factors affect the friction coefficient, including surface texture, moisture levels, temperature, and the type of material in contact with the concrete. Rough surfaces and dry conditions typically increase friction, while smooth or wet surfaces decrease it.

We measure the friction coefficient with tools like tribometers, which check the resistance between concrete and another material. We use the results to figure out the coefficient and help make construction decisions.

Yes, the friction coefficient can change due to factors like wear and tear, weather conditions, or the application of coatings. Regular maintenance and surface treatments can help maintain or adjust the coefficient.

Static friction occurs when there is no movement between the concrete and another material, while kinetic friction happens when there is motion. Static friction is generally higher, as it takes more force to start movement than to maintain it.

Water reduces the concrete friction coefficient by creating a slippery surface. This is why wet roads or sidewalks can be more dangerous, as they provide less traction for vehicles or pedestrians.

Yes, we can increase the coefficient by making the surface rougher, adding coatings, or mixing sand or gravel into the concrete.

For roads and bridges, a higher friction coefficient ensures that vehicles have proper traction, especially in adverse weather conditions. This helps prevent accidents caused by skidding or loss of control on slippery surfaces.

Materials like rubber, steel, and glass often interact with concrete in construction. Each material has a different friction coefficient when in contact with concrete, influencing decisions in areas like flooring, road construction, and industrial applications.